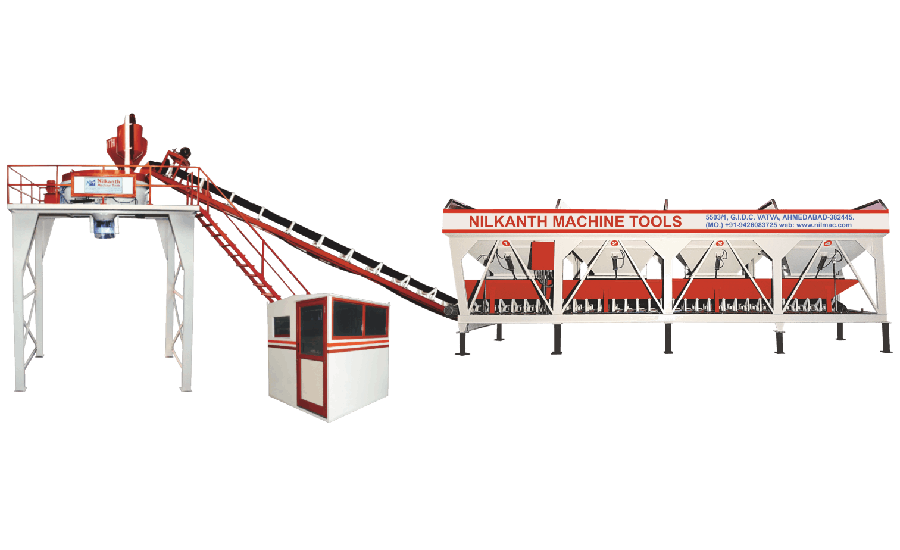

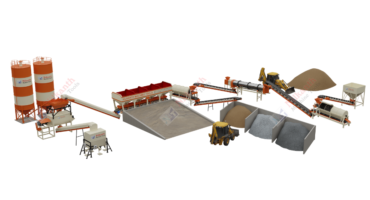

Stationary Concrete Batching Plant:

Our concrete batching plant machine is a highly efficient and reliable solution designed to meet the demands of modern construction projects. Engineered for precision, it ensures the consistent mixing of high-quality concrete with minimal downtime.

Key Features:

- Robust Design: Built with durable materials to withstand heavy-duty operations and challenging environments.

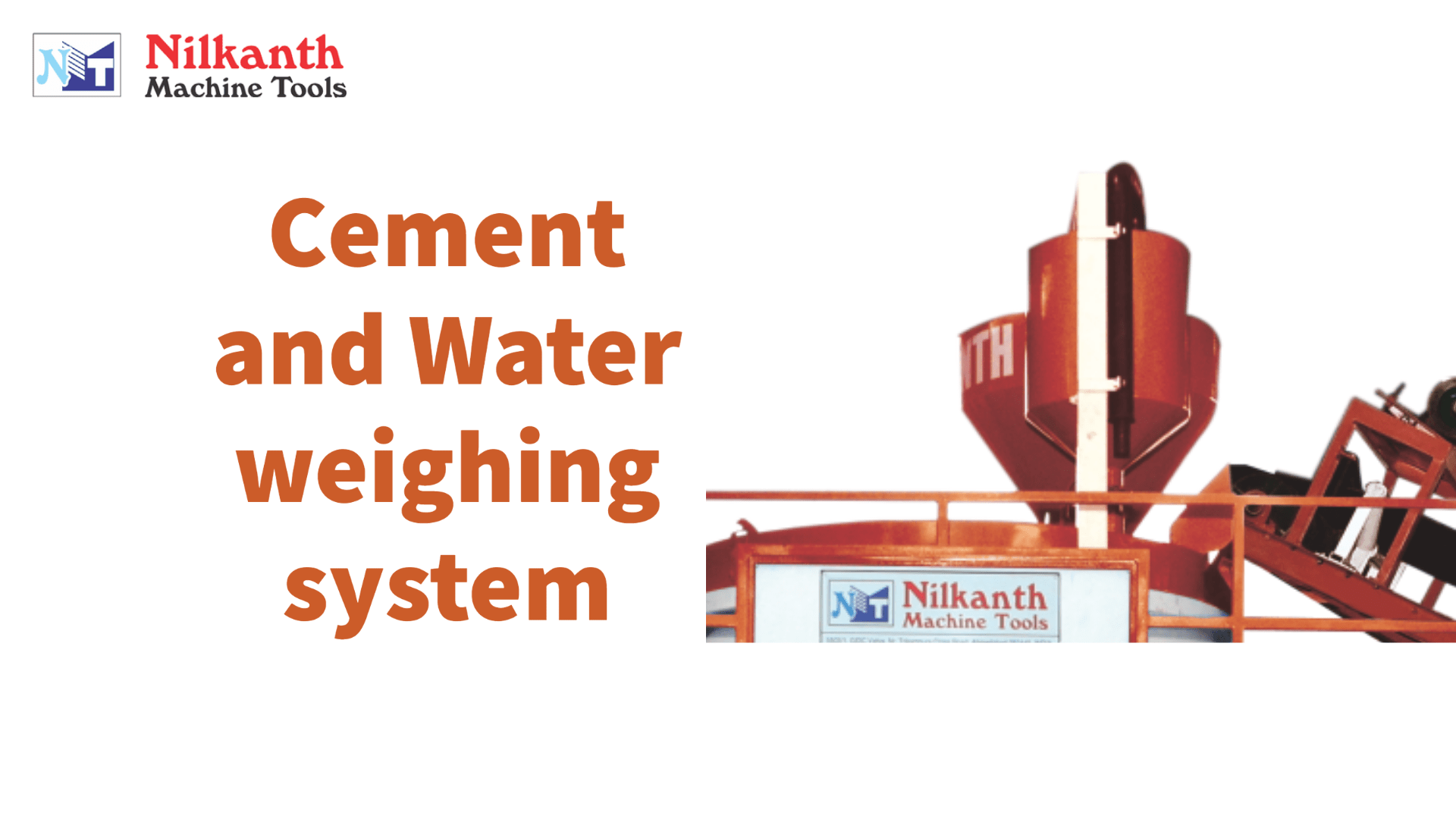

- High Accuracy: Equipped with advanced sensors and weighing systems to deliver precise proportions of cement, aggregates, water, and admixtures.

- Versatile Configuration: Available in stationary and mobile variants to suit diverse project requirements.

- Automated Operation: Integrated with user-friendly control systems for seamless and efficient batching processes.

- Energy Efficient: Designed to optimize energy consumption without compromising performance.

- Customizable Output: Supports varying capacities to accommodate small to large-scale construction needs.

Application: Ideal for infrastructure projects, pre-cast industries, road construction, and commercial and residential developments, this machine ensures timely and cost-effective concrete production. Enhance your operational efficiency with our state-of-the-art concrete batching plant.

Product has varied options, click here to contact us for more info.

Technical Specifications

| Model | SP-20 | SP-25 | SP-30 | SP-45 | SP-60 | SP-75 |

|---|---|---|---|---|---|---|

| Type | Fix/Stationary | Fix/Stationary | Fix/Stationary | Fix/Stationary | Fix/Stationary | Fix/Stationary |

| Mixer | Pan mixer | Pan mixer | Pan mixer | Pan/Twin Shaft mixer | Pan/Twin Shaft mixer | Pan/Twin Shaft mixer |

| Output Capacity | 20 Cu.M/Hr | 25 Cu.M/Hr | 30 Cu.M/Hr | 45 Cu.M/Hr | 60 Cu.M/Hr | 75 Cu.M/Hr |

| Batch Capacity | 0.4 Cu.m/400 Ltrs. | 0.45 Cu.m/450 Ltrs. | 0.5 Cu.m/500 Ltrs. | 0.75 Cu.m/750 Ltrs. | 1.0 Cu.m/1000 Ltrs. | 1.25 Cu.m/1250 Ltrs. |

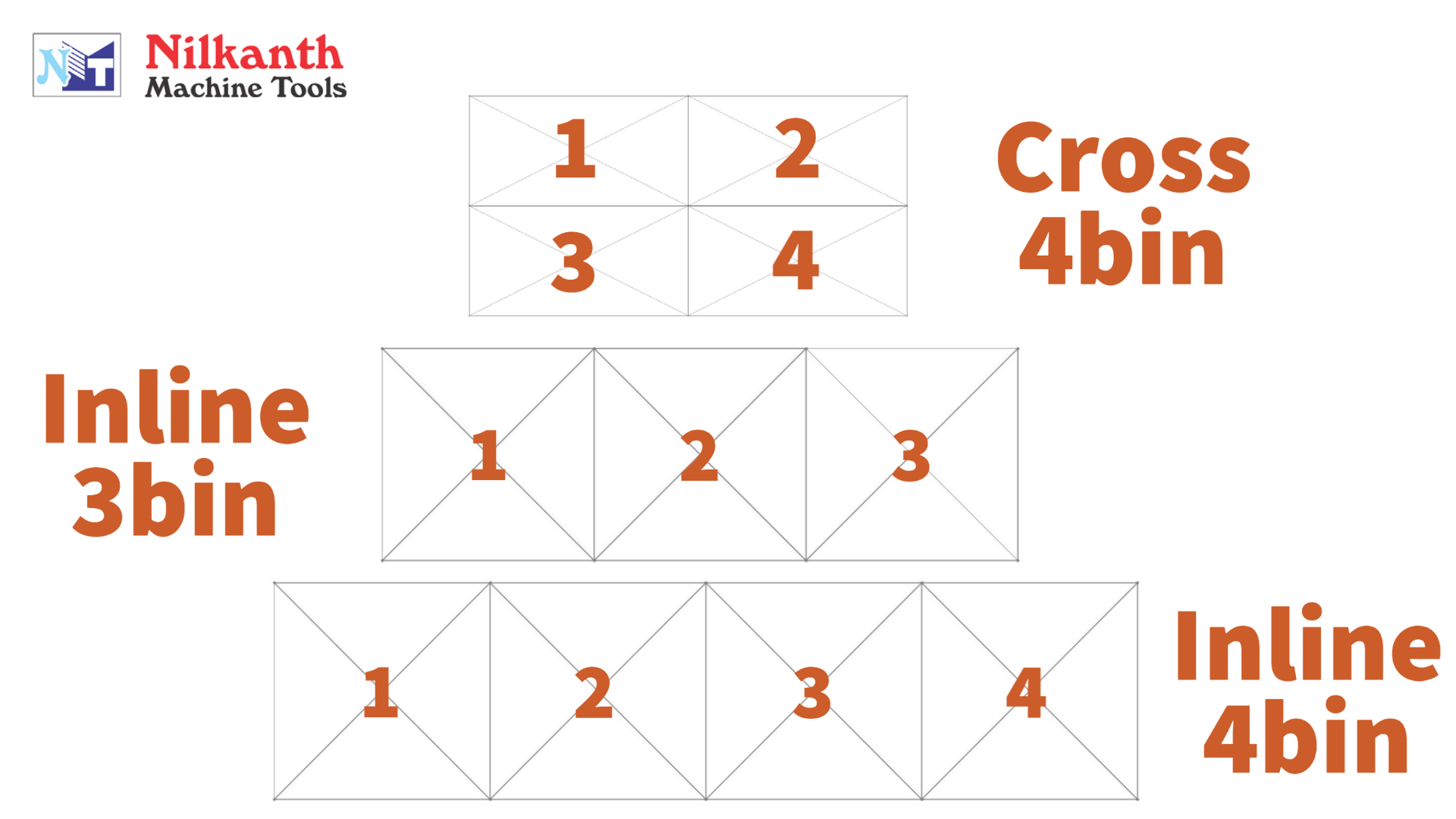

| Storage Hoppers | 2/4 X 2.5 M^3 (Each Bin) | 2/4 X 2.5 M^3 (Each Bin) | 4 x 5 M^3 (Each Bin) | 4 x 5 M^3 (Each Bin) | 4 x 7 M^3 (Each Bin) | 4 x 10 M^3 (Each Bin) |

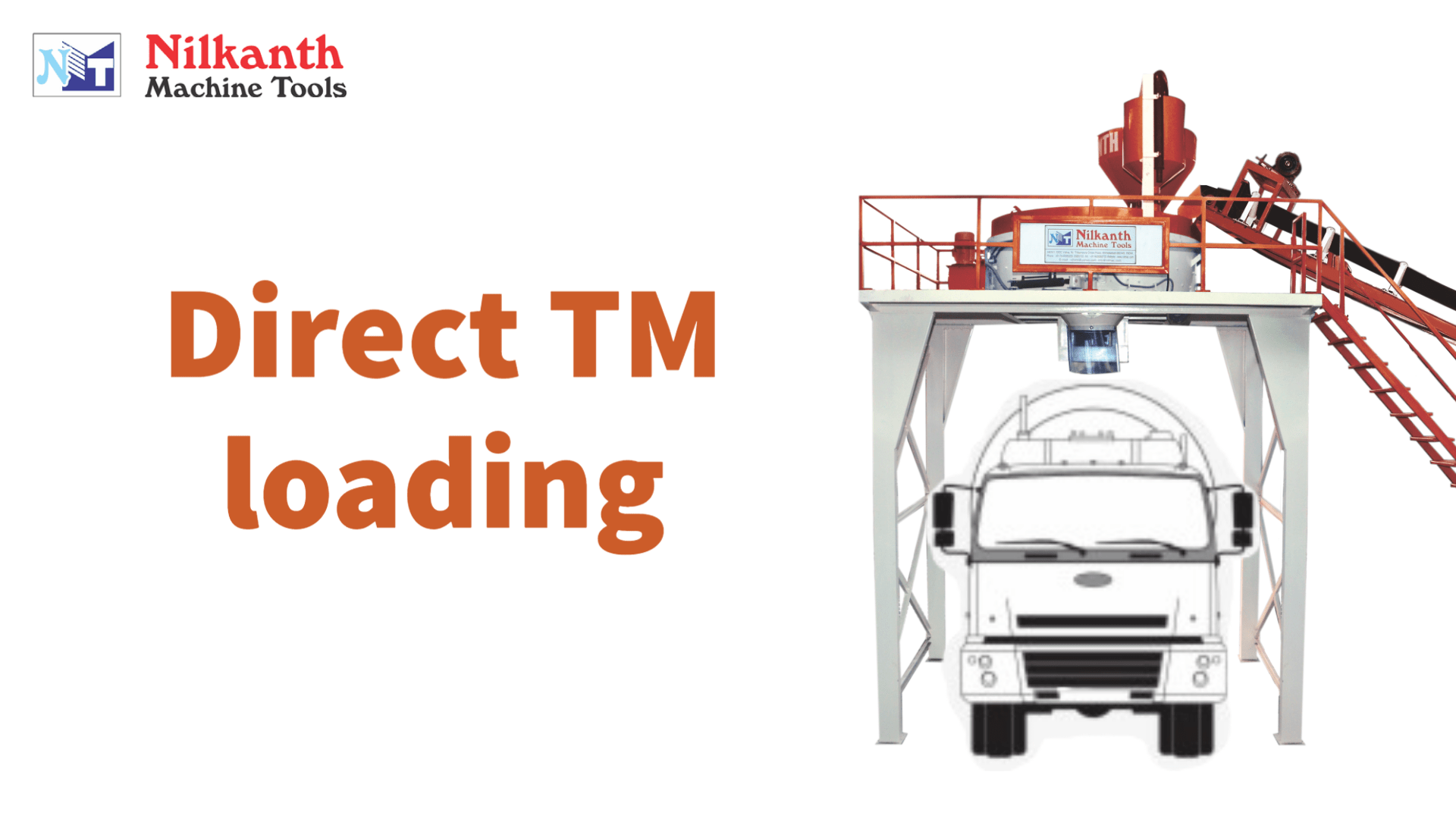

| Discharge Height | 13 Feet | 13 Feet | 13 Feet | 13 Feet | 13 Feet | 13 Feet |

| Main Motor | 20 H.P | 25 H.P | 30 H.P | 40 H.P | 40 H.P | 50 H.P |

| Water Pump | 1.5 H.P. | 2.0 H.P. | 3.0 H.P. | 3.0 H.P. | 5.0 H.P. | 5.0 H.P. |

| Additive Pump | 0.5 H.P. | 0.5 H.P. | 0.5 H.P. | 0.5 H.P. | 0.5 H.P. | 0.5 H.P. |

| Power Required | 47 H.P. | 52 H.P. | 66 H.P. | 81 H.P. | 90 H.P. | 100 H.P. |

| Cement Silo | 1.5 T | 1.5 T | 1.5 T | 2.0 T | 2.0 T | 3.0 T |

| Control Cabin | L7 X W5 X H6 Feet | L7 X W5 X H6 Feet | L7 X W5 X H6 Feet | L7 X W5 X H6 Feet | L7 X W5 X H6 Feet | L7 X W5 X H6 Feet |